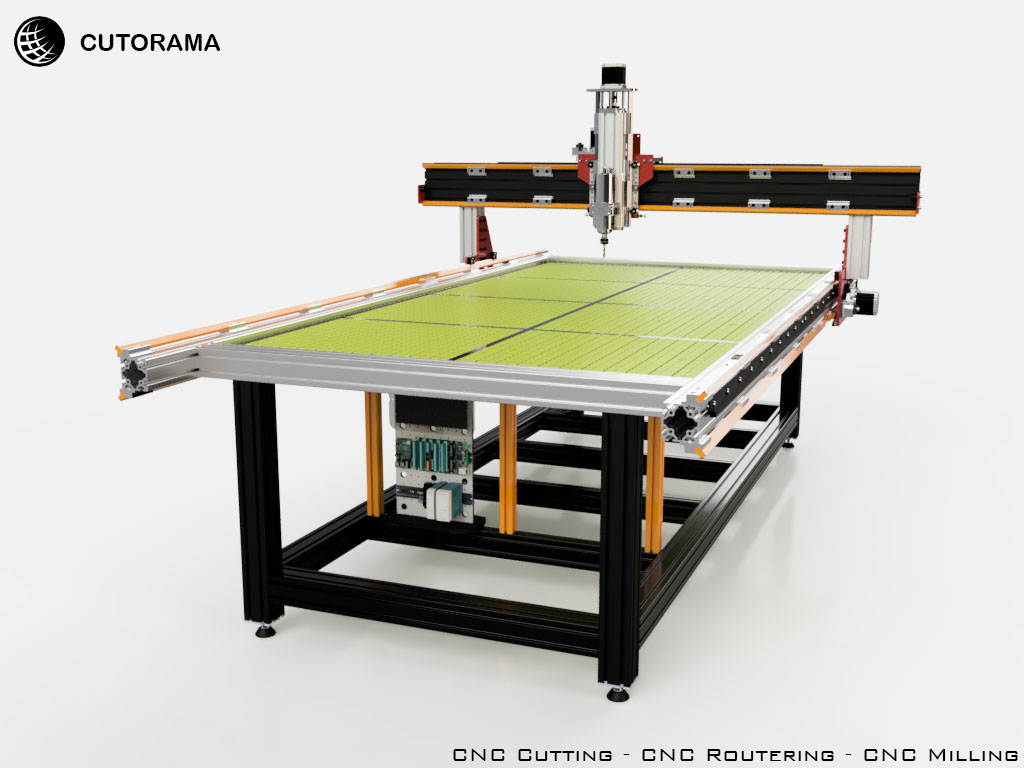

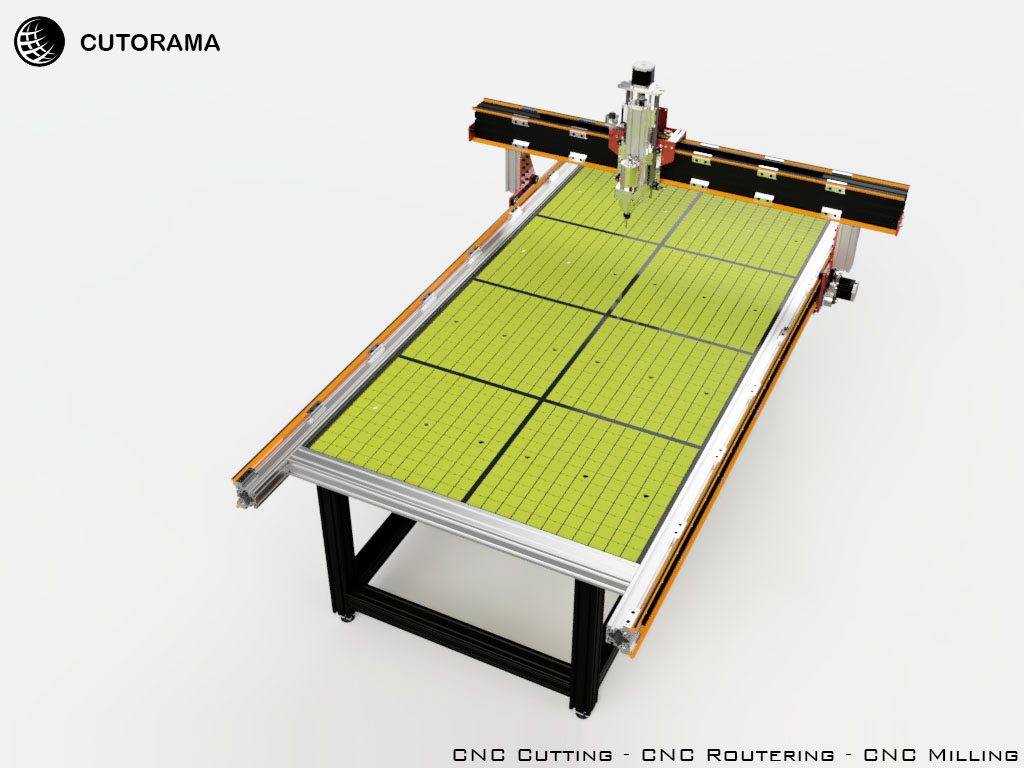

Cutorama v22 offers CNC cutting, CNC Routing and CNC Engraving on our custom large format gantry based machine. The CNC is a digitally controlled cutting machine that follows the tool paths programmed in CAM software. CAM is Computer-Aided Manufacturing. Often a 3D model is created to represent the final part or parts. Tool paths are programmed to follow the surfaces of the model so the CNC can reproduce one or many units that are identical within a few thousands of an inch. This makes the CNC optimal for when complexity and repeatability are required in product runs.

Our CNC machine is most often used for projects such as producing panels for custom cabinet makers, parts for various product producers and shapes for forms for manufacturers. There are many uses for such a machine. It can mill in three directions simultaneously in the XYZ coordinates. Or left to right, front to back, up and down. This allows for precise movements of flat stock with attributes like holes, rabbets, dados or groves. Or in full 3-dimensional mode can be utilized for carving anything from a company logo to a human figure.

The CNC uses a physical cutter called and end mill which plows or routes the material. Many CNC machines can cut solid materials of 3" thick or more. However not that it is advisable to cut thicker stock with multiple passes. Cutting no deeper than the diameter of the end mill per pass is a good starting point. When calculating the cost of a project thickness matters. Cutting shapes in 1" MDF would take twice as long as cutting them in 1/2" MDF. Material of .25" can often make use of the Co2 Laser which has no physical contact with the material. Therefore it can cut at faster feed rates. For material which needs to spun cylindrically while milling a CNC Lathe might be an optimal machine.