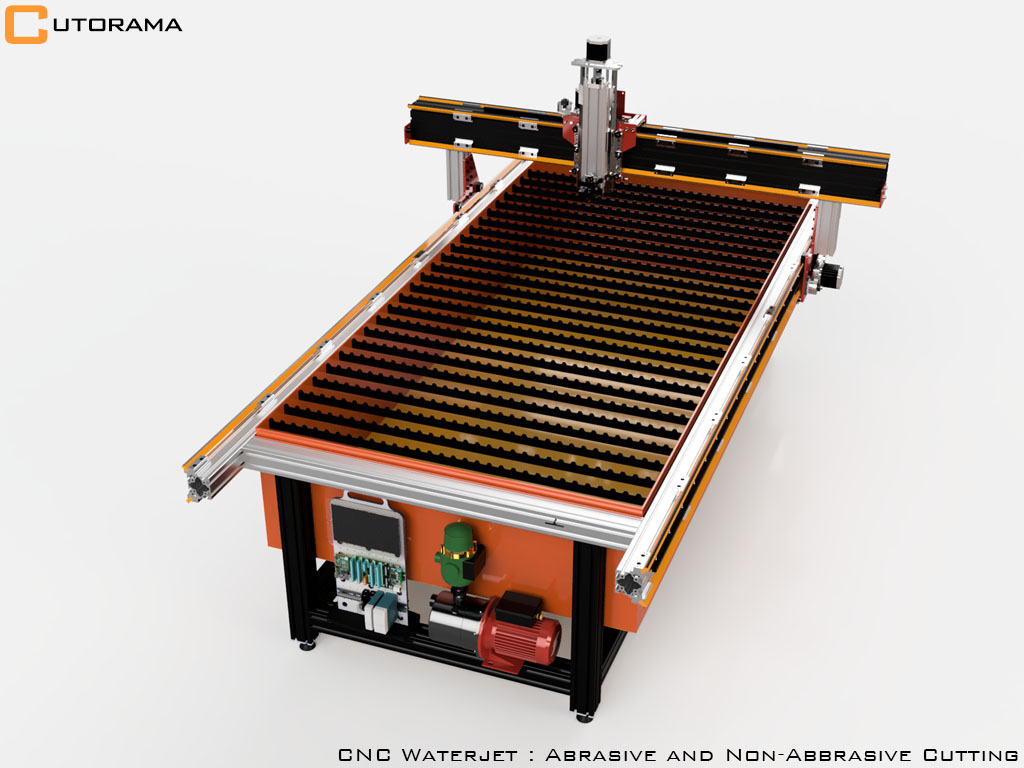

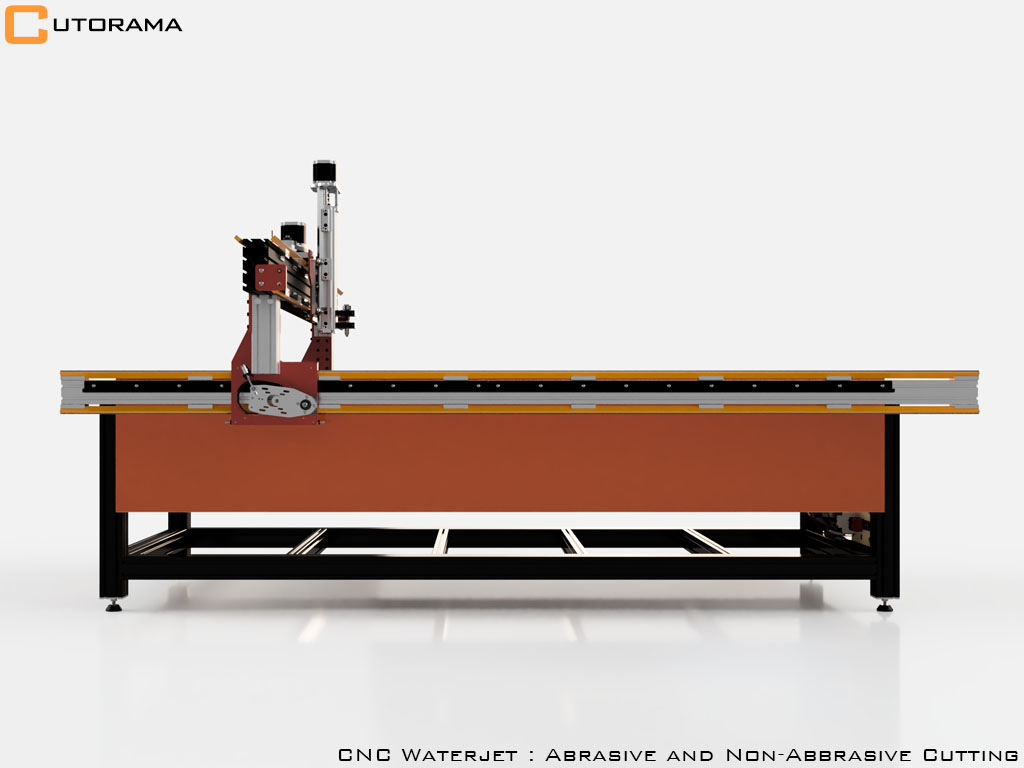

Waterjet cutting offers heat-free precision with a variety of materials. Ultra high pressure water though a very small nozzle creates that cuts very with a small kerf cut though dense stock. A water jet cutter can be utilized with and without abrasives mixed with the high pressure water stream. No abrasives added for softer materials. With abrasives for harder materials such as ferrous metal or stone. No heat-affected zone (HAZ) offers some advantages over CNC plasma cutting such as not altering intrinsic properties. Materials which can be cut are steel, stainless steel, aluminum, brass, copper, rubber, granite, marble, glass, ceramics, composites, foam and sometimes wood. Water-Jet CNC cutting is done without the use of end mills which need replacing with dull or when breaks. There is a small consumable cost when adding abrasives to the cutting process. Our machine design is a 3-Axis with water pressure ranging from 30,000 to 80,000. Cutorama will be offering waterjet cutting services 4th quarter of 2021.