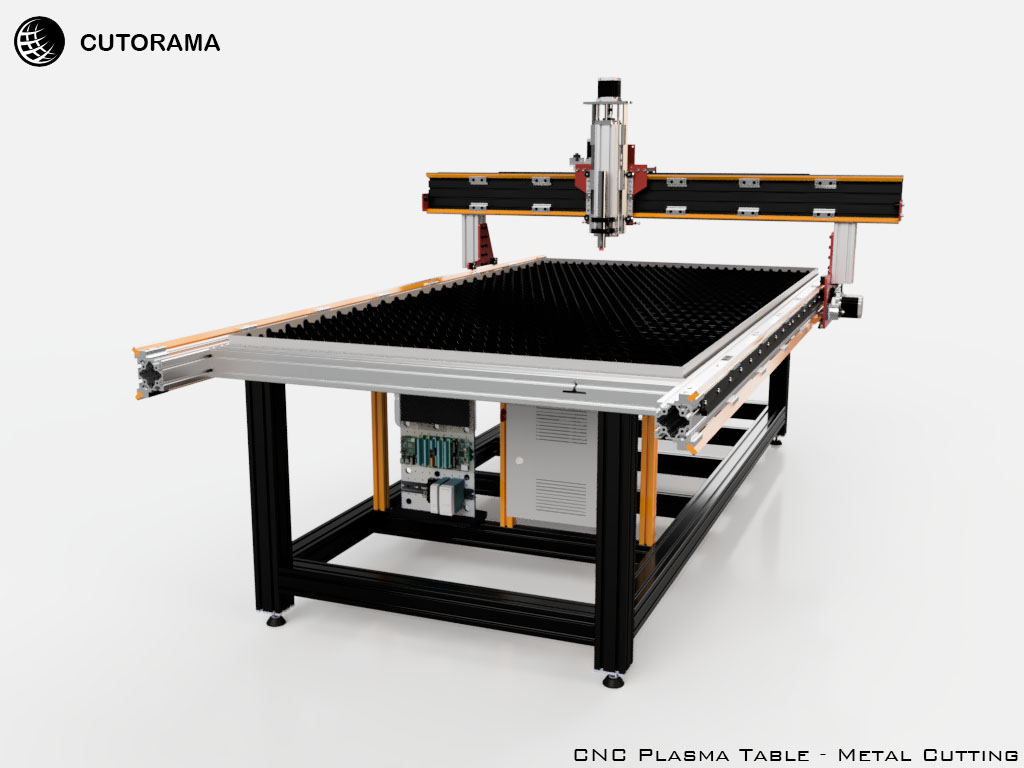

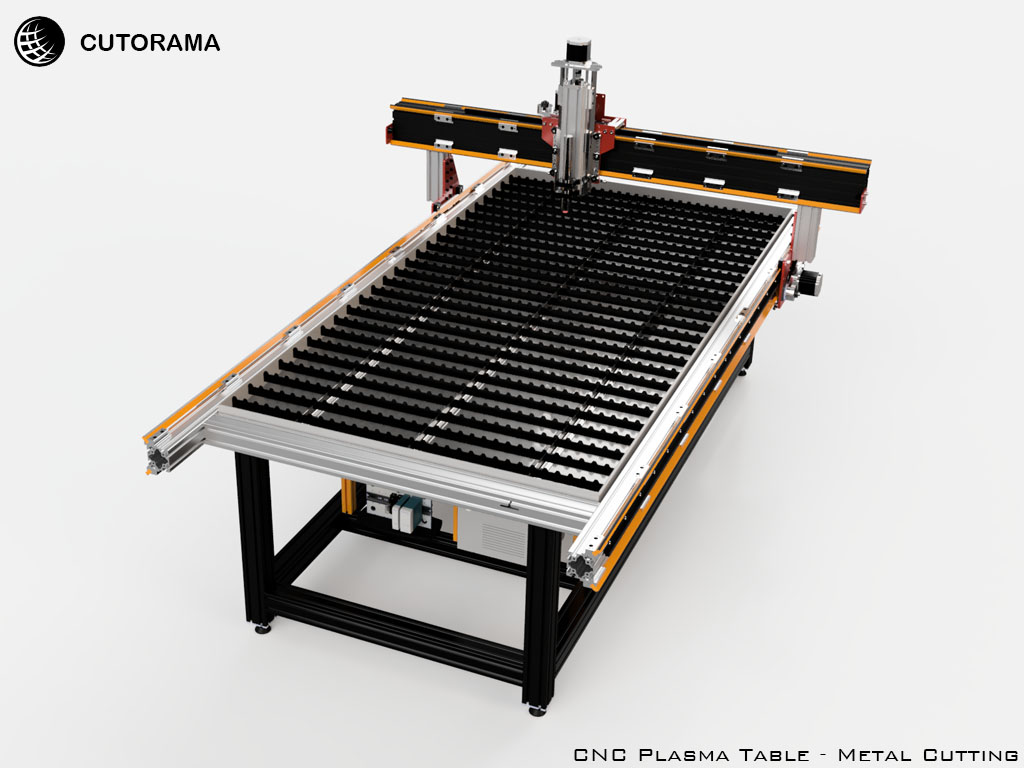

A Plasma torch or CNC controlled plasma table can be used to cut electrically-conductive materials including steel, stainless-steel, aluminum and most other metals means with a controlled accelerated jet of hot plasma. Plasma cutting is a low cost method mostly utilized for cutting ferrous and non-ferrous metal sheet and plate stock, though some machines have a rotary axis for cutting pipe. CNC plasma tables are used for a wide range of metal fabrication applications where accuracy and repeatability are desired. Cut material can be heat-affected due to the nature of the cutting torch. This is fine for non critical metal parts such as signage, brackets or non-precision parts. For no heat-affected zone (HAZ) parts a CNC waterjet cutter might be a better option. Metals that can be cut include steel, stainless steel, aluminum, brass and copper. Cutorama will be offering plasma cutting services 3rd quarter of 2021.