Industry 4.0 is simply the fourth industrial revolution digitally transforming the automation industry.

Industry 4.0 promotes the digitalization of all aspects of a manufacturing enterprise. This promotes electronic and informational communicate though out the business that was traditionally seperated between information techologies and operational techmologies. Openess is a defining structure for the modern smart factory. Manufacturing production well integrated with business processes. Horizontal integration - processes on production floor, material warehouses, possibly with multiple production facilities, and including supply chain vendors Vertical integration - layers of an organization stack electronic communicate data flows freely from the shop floor to the top floor and back down again. Individual knowledge silos must be deprecated and replaced with realtime information sharing across an entire enterprise.

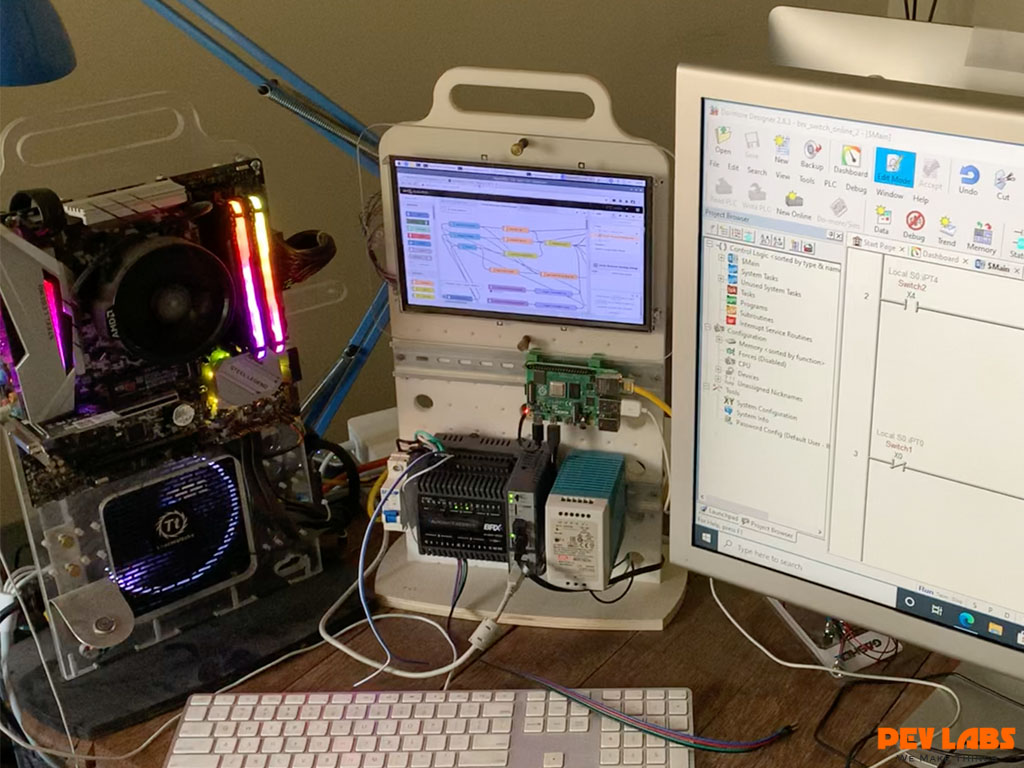

Intelligent business performance is replacing legacy paper based systems. Transformative technologies are merging with traditional manufacturing equipment to create seem-less communication between the office, plant floor, warehouse and supply vendors. Industrial Internet of Things are creating smart factories with connected machines. Machine to Machine communication (M2M) working alongside human reasoning are forming cyber physical systems. Smart machines with IIoT sensors that are networked talking to each other and unified namespace and centralized data lake. Continuous large volumes of data can be analyzed with machine learning for predictive maintenance. Inter-connected supply chains, warehouse management and logistic companies are all queued in. An ecosystem where everyone in the stack exchanges information in real time. Cobots working alongside human workers. Digitalization of everything in a company and eliminating data silos to solve complex problems.

Industry 3.0

Industry 4.0

For more visit our services deep dive page.

More on the history of industry here.

Cutorama offers fast, casual, friendly design and cutting services for your products or project.

Be it a single part for parent and child to finish their soapbox derby project or start-up that needs 50 widgets for their initial product offering.

One-offs to on demand digital fabrication we are flexible and open to new ideas.

IIoT enabled custom built machinery can provide various metrics about your milling.

This includes live stream or captured data and video of a milling run.

Data supplied to you for machine learning process optimization or human consumption.